CELEBRATING 50 YEARS IN NDT & INSPECTION

Comprehensive Range of Inspection & Engineering Services

Welcome to IPEC Inspection Ltd., a 100% fully Irish owned and operated engineering & inspection company based in Co. Cork since 1973. We are a leader in Welding Inspection & Non-Destructive Testing (NDT) solutions that redefine safety, reliability, and precision across industries. With an unwavering commitment to excellence, we stand as your trusted partner in ensuring the integrity of materials, structures, and components without compromise.

At IPEC, we understand that the quality of your products, projects, and operations is non-negotiable. Our NDT & Engineering expertise empowers you to make informed decisions, prevent failures, and optimize performance, all while reducing downtime and cost. We approach asset health impartially with an experienced led, integrity based approach and with a team of seasoned NDT professionals and cutting-edge technology at our core, we offer a comprehensive suite of services tailored to your every need.

Our Expertise

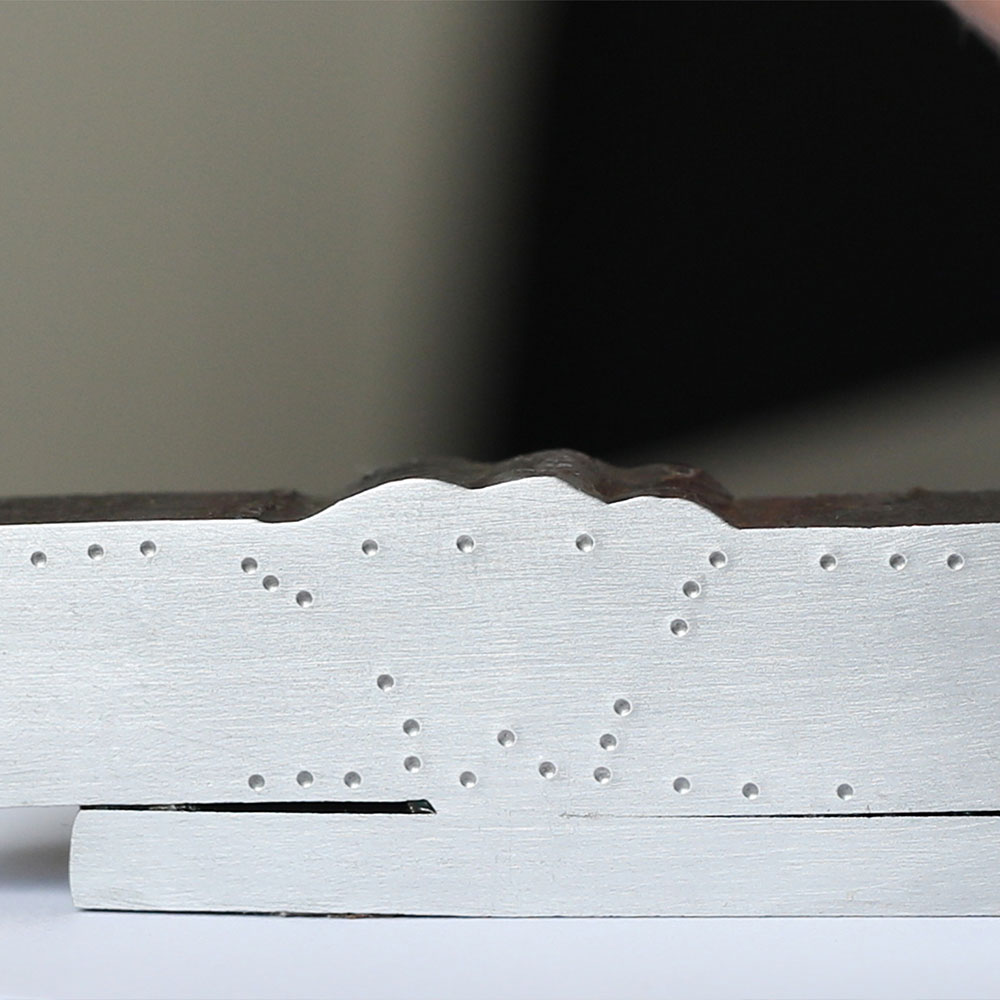

Backed by decades of collective experience, our experts are well-versed in a wide array of NDT techniques. From phased array ultrasonic testing to radiographic examination, magnetic particle inspection to positive material identification (PMI), eddy current testing to advanced 3D digital solutions, we deliver insights that transcend the surface and penetrate the heart of your materials and structures.

We understand that every project is distinct. That’s why we collaborate closely with you to develop custom-tailored NDT strategies that align with your specific goals. Our solutions seamlessly integrate into your workflow, ensuring minimal disruption while maximizing the accuracy of our assessments.

Cutting-Edge Technology

In a rapidly evolving technological landscape, we stay ahead of the curve. By harnessing the power of innovative tools, software, and equipment, we provide you with NDT solutions that are not only accurate but also efficient and future-ready.

Industry Impact

From pharmaceuticals to manufacturing, energy to construction, our impact spans across sectors. We’ve been instrumental in ensuring the safety of critical infrastructure, optimizing manufacturing processes, and bolstering the performance of vital components.

Collaborative Approach

We don’t just deliver results; we foster partnerships. Your success is our success, and we are dedicated to working closely with you, addressing your challenges, and celebrating your achievements.

How can we help?

We offer Non Destructive Testing (NDT), Advanced NDT, Pipework & Vessel Inspection, Welding Inspection & Certification, Asset Owner Consultation, 3rd Party Vendor Assessment, Coating & Painting Inspection, Corrosion Assessment, Engineering & Pipeline Management Services, Pipeline Defect Assessment & Quality Assurance to ensure all our clients have complete confidence in their industrial assets.

Our team of highly skilled engineers & inspectors are experts in their field which helps ensure operational reliability & optimises performance across a wide range of operations. We believe our wealth of experience maintains a safe & productive asset assessment system for our clients here in Ireland and abroad.

INSPECTION & ENGINEERING SERVICES

Our Fields of Expertise

Speciality Services

- Non Destructive Testing (NDT)

- Vessel Inspection

- 3rd Party Vendor Assessment

- Pipeline Management & Supervision

- Advanced NDT

- Quality Assurance

- Pressure System Regulation Inspections (PSR’s)

- Coating, Painting & VS02 Inspections

- Welding Inspection & Certification

- Corrosion Assessment & Analysis

- 3D Laser Scanning & Assessment

- Asset Owner Consultation

INDUSTRIES WE DELIVER OUR SERVICES TO

Industry Sectors

Pharmaceutical

Oil & Gas

Power Generation

Construction

Petrochemical

Refining

IPEC Management

OUR TEAM

Michael Murphy

Managing Director

Dan Hallissey

Managing Director

Brendan Creedon

Gas Networks Operations Manager

(Southern & Western Region)

James Murphy

NDT Operations Manager

Projects Manager

Chris Dillon

Gas Networks Operations Manager

(Eastern Region)

Gerard Creedon

Contracts Manager

Angela O’ Rourke

Admin / Sales

Rebecca O’ Donovan

Accounts / HR