Phased Array Ultrasonics in Lieu of Site Radiography

As the restrictions in the use of X-Ray & Gamma on sites has increased over the years, the need for alternative weld inspection methods and techniques such as Phased Array [...]

Phased Array Corrosion Mapping

Phased Array Corrosion Mapping is a quantitative way to inspect a material where oxidation or erosion has reduced its wall thickness. Corrosion is the degradation of metallic structures which can [...]

Pulsed Eddy Current (PEC)

Pulsed Eddy Current (PEC) is an inspection technique for inspecting carbon steel objects such as pipes and vessels without the need for contact with the steel surface. PEC can measure [...]

Corrosion Under Insulation / Fireproofing (CUI / CUF)

Corrosion Under Insulation (CUI) refers to the phenomenon of corrosion occurring on the external surface of a metal substrate that is covered by an insulation material. It is a significant [...]

Holiday Detection / Spark Testing

Pipe wrap and holiday detection are two related techniques used in the maintenance and repair of pipelines. Pipe wrap involves the application of a protective layer or wrapping around a [...]

Remote Visual Inspection (RVI)

Remote visual inspection (RVI) is a non-destructive testing method that involves the use of specialised tools and equipment to inspect and evaluate the condition of structures, components, and systems from [...]

Leak Testing

Leak testing is a process used to detect and locate leaks in a variety of systems and components, including pipelines, tanks, valves, and equipment. The purpose of leak testing is [...]

Positive Material Identification

Positive Material Identification (PMI) is a process of analyzing and identifying the composition of metallic materials used in various industries such as manufacturing, construction, and maintenance. The purpose of PMI [...]

Welding Inspection

Welding inspection is the process of examining and evaluating welded joints to ensure they meet the required standards for safety, quality, and functionality. The inspection can be performed during or [...]

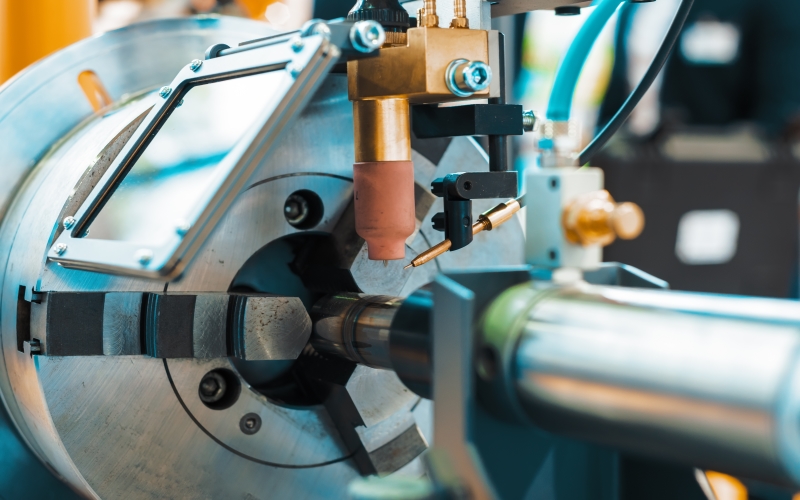

Mechanised vs Automatic Welding

Welding operators and weld setters are both important roles in the welding industry, but they have different responsibilities and skill sets. A welding operator is a person who operates a [...]

Destructive & Non-Destructive Testing

Destructive Testing Destructive testing (DT) is a type of testing that involves the intentional destruction of a material, component or assembly to evaluate its mechanical, physical or chemical properties. DT [...]

Weld Procedure Qualification Record

Qualified welding procedures are required for production welding, repair welding & build up welding. The primary purpose of a welding procedure qualification is to demonstrate that the joining process proposed [...]

Advanced UT (Phased Array & ToFD) in Lieu of Radiography

As the restrictions in the use of Industrial Radiography (RT) has increased over the years, the need for alternative weld inspection methods and techniques such as Time of Flight Diffraction [...]

Ultrasonic Examination of Boilers

Introduction to Shell Boilers & their Examination Since 1993 Inspection Organisations have noted a marked increase in the number of shell boilers exhibiting cracks at shell-to-endplate and furnace-to-endplate welds. Records [...]

Fabrication of Artificial Kidney Stones Using Ultrasound

Delighted to help out Dr. O' Connor on this study aiming to develop artificial kidney stones for ex vivo studies by using an ultrasound transmission technique, from which the corresponding [...]

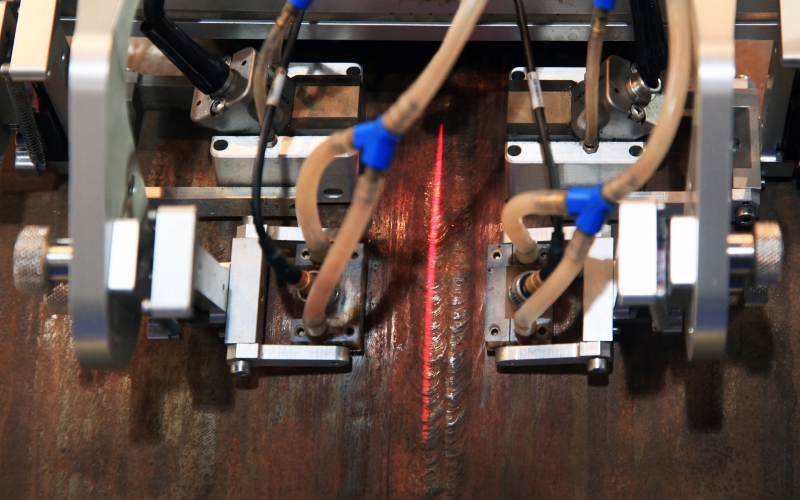

Corrosion Monitoring & Assessment of Gas Pipelines using 3D Scanners

Inspection of Gas Pipelines Without proper maintenance, the lifespan of gas pipelines can be greatly reduced, which can subsequently lead to people and the environment being exposed to potential hazards [...]

Visual Boroscope Inspection

A boroscope is an optical instrument used in industrial applications to view the interior of technical hollow bodies or interior surfaces in tubes, pipes, holes, gas turbine engines or other [...]

Visual Inspection

Visual Inspection (VI), or visual testing (VT), is the oldest and most basic method of inspection. Visual examination is generally used to determine such things as the surface condition of [...]