OUR SERVICES

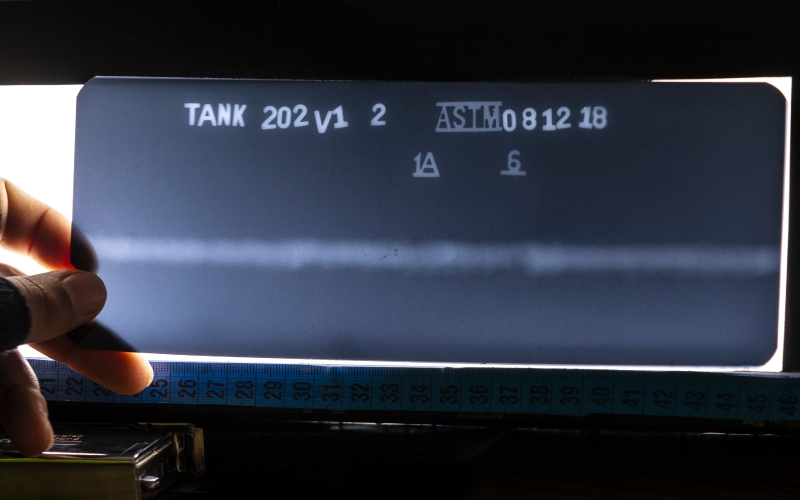

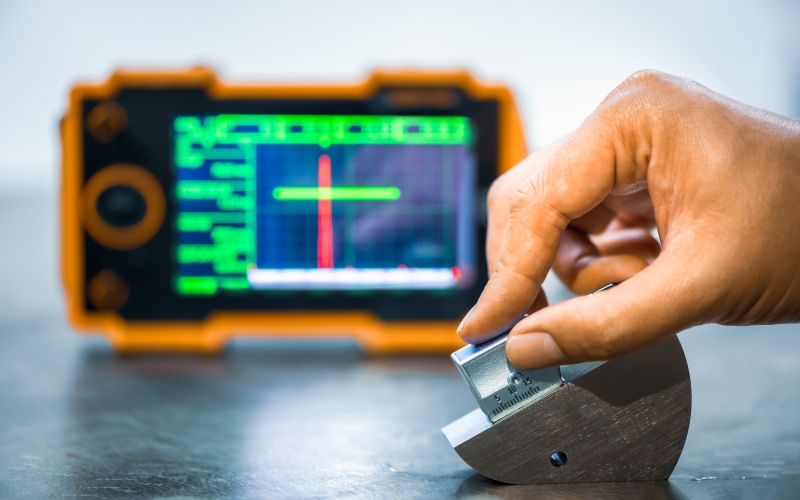

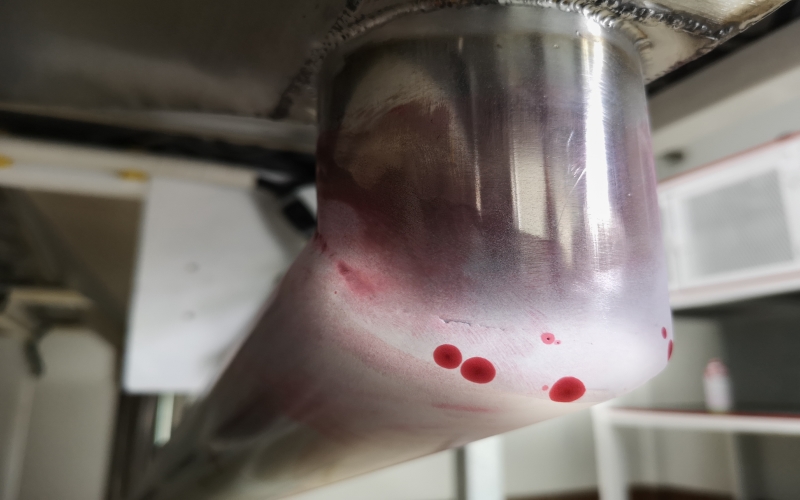

Non Destructive Testing (NDT)

- Industrial Radiography (X & Gamma)

- Ultrasonic Weld Inspection

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Ultrasonic Thickness Measurements

- Eddy Current Inspection

- Visual Inspection

- Boroscope Inspection (High Purity Tubing & Sch. Pipework)

- Remote Visual Inspection (Internal Vessel Inspection)

- Leak Testing

- Spark Testing / Holiday Detection

OUR SERVICES

Advanced NDT

- 3D Laser Scanning & Defect Analysis

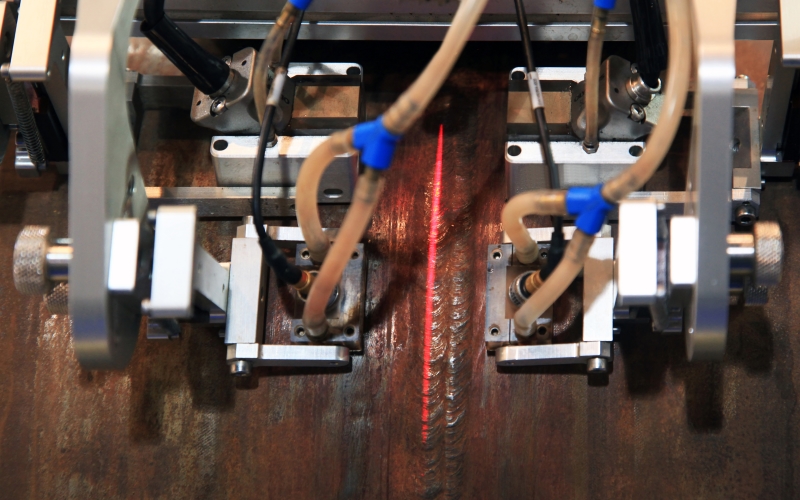

- Phased Array Ultrasonic Weld Inspection

- Ultrasonic Examination of Boilers (In accordance with BINDT & SAfed Guidelines)

- Time of Flight Diffraction

- Manual & Automated Phased Array Corrosion Mapping

- Corrosion Inspection, Assessment & Survey

- Pulsed Eddy Current (PEC)

- Corrosion Under Insulation (CUI) & Corrosion Under Fireproofing (CUF)

- Environmental Assisted Cracking Inspection

e.g. High Temperature Hydrogen Attack (HTHA), Hydrogen Induced Cracking (HIC), Polythionic Acid Stress Corrosion Cracking (PASCC), Hydrogen Stress Cracking (HF) & Carbonate Stress Corrosion Cracking (ACSCC)

OUR SERVICES

Metallurgical Services

- Positive Material Identification (PMI)

- Hardness Testing (Leeb, Rockwell & UCI)

- Ferrite Measurement

- Surface Roughness Measurement

- Material Analysis

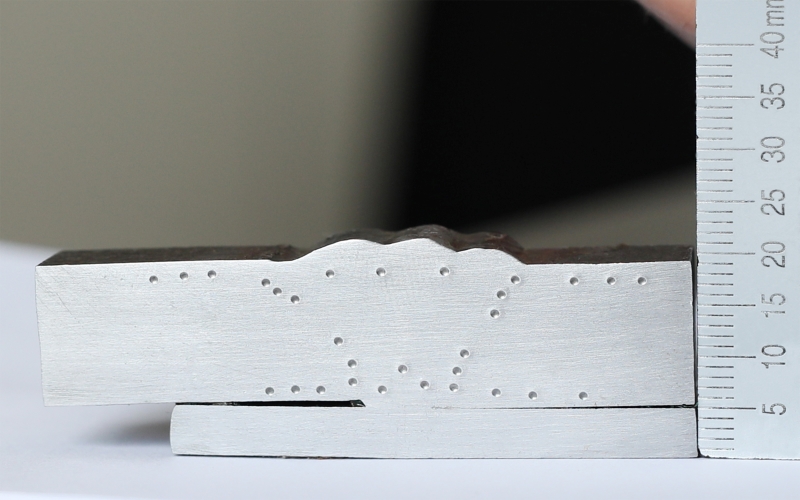

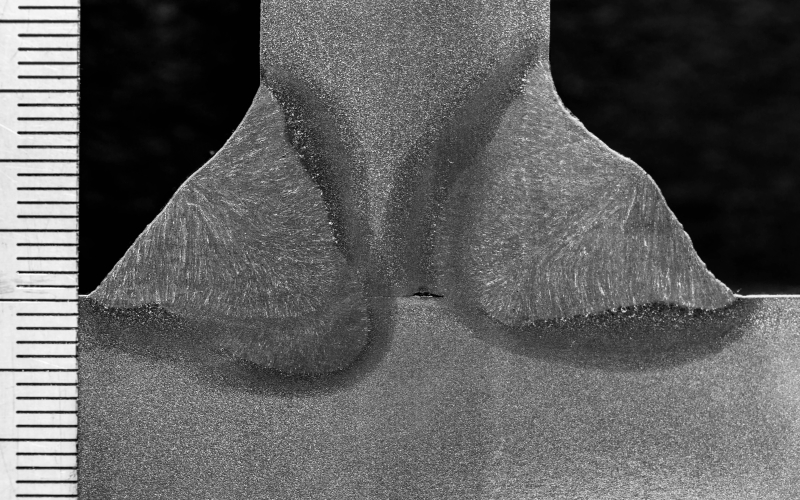

- Macro Examination

- Fracture Examination

OUR SERVICES

Welding Inspection & Certification

- Preliminary Welding Procedure Specification (pWPS)

- Welding Procedure Qualification Record (WPQR)

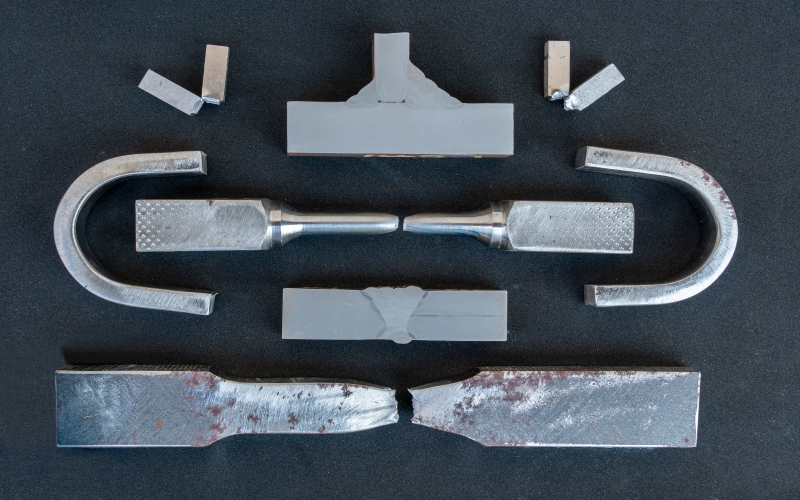

- Destructive & Non Destructive Testing of Welds

- Qualification Testing of Welders

- Qualification Testing of Welding Operators & Weld Setters for Mechanised and Automatic Welding

- Welder & Welder Operator Revalidation

- Welding Procedure Specification (WPS)

- Welding Inspection

OUR SERVICES

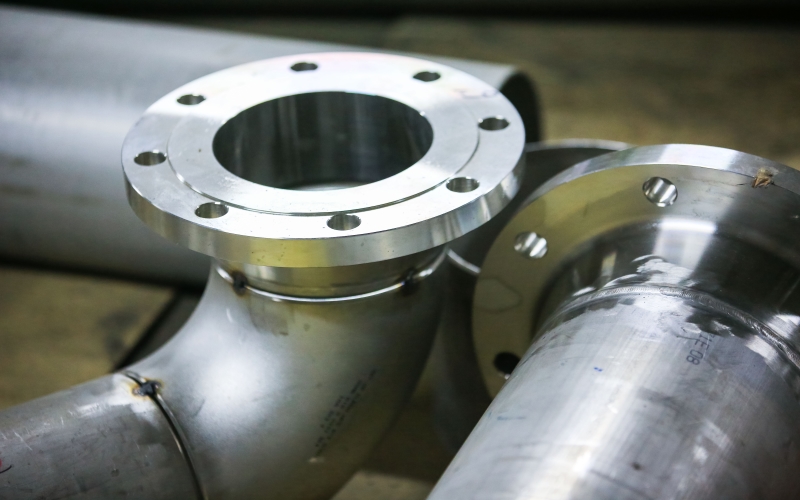

Pipeline Inspection & Management Services

Management of a Gas Pipeline Network is a sophisticated 24hr operation. Materials used during Distribution and Transmission construction vary, thus creating risk factors that differ greatly between different types of pipeline projects.

Managing and monitoring key tasks requires an enormous level of planning. Having an adequate amount of inspection resources with the requisite skills, knowledge & experience is paramount in managing a pipeline system.

IPEC Inspection Ltd. provides pipeline inspection services to support & safely manage the Gas Networks Ireland (GNI) pipeline network nationwide.

We provide;

- 3D Laser Scanning & Pipeline Defect Assessment (ASME B31 G etc.)

- Pressure System Regulation Inspections (PSR’s) on transmission AGI’s including VS02 inspections.

- Specialised Non Destructive Testing

- Provision of pipeline inspectors & equipment to supervise excavation works close to GNI transmission and distribution pipelines

- Provision of experienced management agents to manage all aspects of the GNI inspection works

- Provision of qualified welding inspectors & equipment to supervise welding works on pipelines and within PRI’s as required

- Provision of construction supervision

- Provision of painting inspection services & supervision of painting works

- Provision of coating & wrapping inspection services & supervision of works

- Provision of inspectors to carry out rural line walks of transmission lines across the countries pipeline routes

- Carry out surveys on transmission watercourse crossings

- Supervision of transmission & distribution pipelines and within above ground installations (AGI’s)

- Leak surveys

- Administration resources

OUR SERVICES

Asset Integrity

- Asset Owner Consultation & Quality Assurance

- Pressure Vessel Inspection

- Tank Inspection

- Pipework Inspection

- Pipeline Inspection

- Corrosion Assessment & Analysis

- Pressure Systems Examination

- 3rd Party Vendor Assessment

- Hydro Test Verification

- Risk Based Inspection

- Coating & Painting Inspection and Assessment